LABORATORY Mechanical Engineering

Third Semester

ENGINEERING MATERIALS

| Sr. No. | LIST OF PRACTICALS |

| 1 | Classification of about 25 specimens of materials/machine parts into: (i) Metals and non metals (ii) Metals and alloys (iii) Ferrous and non ferrous metals (iv) Ferrous and non ferrous alloys |

| 2 | Given a set of specimen of metals and alloys (copper, brass, aluminium, cast iron, HSS, Gun metal); identify and indicate the various properties possessed by them. |

| 3 | a) Study of heat treatment furnace. b) Study of a thermocouple/pyrometer. |

| 4 |

Study of a metallurgical microscope and a specimen polishing machine. |

| 5 | To prepare specimens of following materials for microscopic examination and to Examine the microstructure of the specimens of following materials: i) Brass ii)Copper iii)Grey iv)Malleable v)Low carbon steel vi)High carbon steel vii) HSS |

| 6 | To anneal a given specimen and find out difference in hardness as a result of annealing. |

| 7 |

To normalize a given specimen and to find out the difference in hardness as a result of normalizing. |

| 8 | To harden and temper a specimen and to find out the difference in hardness due to tempering. |

Applied Mechanics

| Sr. No. | LIST OF PRACTICAL |

| 1 | Verification of the polygon law of forces using gravesend apparatus. |

| 2 | To verify the forces in different members of jib crane. |

| 3 | To verify the reaction at the supports of a simply supported beam |

| 4 | To find the mechanical advantage, velocity ratio and efficiency in case of an inclined plane. |

| 5 | To find the mechanical advantage, velocity ratio and efficiency of a screw jack. |

| 6 |

To find the mechanical advantage, velocity ratio and efficiency of worm and worm wheel. |

| 7 |

To find mechanical advantage, velocity ratio and efficiency of single purchase crab. |

| 8 | To find out center of gravity of regular lamina. |

| 9 | To find out center of gravity of irregular lamina. |

| 10 | To determine coefficient of friction between three pairs of given surface. |

ELEMENTS OF ELECTRICAL AND

ELECTRONICS ENGINEERING

| Sr. No. | LIST OF PRACTICALS |

| 1 | Connection of a three-phase motor and starter with fuses and reversing of direction of rotation. |

| 2 |

Connection of a single-phase induction motor with supply and reversing of its direction of rotation. |

| 3 | Troubleshooting in domestic wiring system, including distribution board. |

| 4 | Connection and reading of an electric energy meter. |

| 5 | Use of ammeter, voltmeter, wattmeter, and multi-meter. |

| 6 | Measurement of power and power factor in a given single phase ac circuit. |

| 7 |

Study of different types of fuses, MCBs and ELCBs. |

| 8 | Study of zener diode as a constant voltage source and to draw its V-I characteristics. |

| 9 | Study of earthling practices. |

| 10 | To draw V-I characteristics of a (i) NPN transistor (ii) thyristor (SCR). |

| 11 | Study of construction and working of a (i) stepper motor and (ii) servo motor. |

METROLOGY AND INSTRUMENTATION

| Sr. No. | LIST OF PRACTICALS |

| 1 |

Internal and external measurements with vernier calliper and microscope. |

| 2 | Measurement of linear dimensions with height gauge and depth gauge. |

| 3 |

Measurement of flatness, concentricity with dial indicator. |

| 4 |

Use of feeler gauge, wire gauge, radius gauge and fillet gauges for checking of standard parameters. |

| 5 | Use of plain plug and ring gauge, taper plug and ring gauge, thread plug and ring gauge and snap gauges. |

| 6 | Measurement of Angle Using: i) Cylindrical rollers and spherical balls and slip gauges. ii) Bevel Protector iii) Sine Bar/Sine Table, Slip Guages, Height Gauge and dial indicator. iv) Angle deckor. |

| 7 |

Measurement of spur gear characteristics: i) Measurement over teeth (M.O.T) by using flange / Disc micrometer. ii) P.C.D run-out using bench centre, mandrel, cylindrical pin and dial indicator. iii) Composite error using Gear Roller Tester and Master Gear. |

| 8 | Measurement of thread parameters by using tool maker’s microscope. |

| 9 |

Measurement of effective diameter of external threads by 2-wire and 3-wire method. |

| 10 |

Measurement of cylindrical bore using cylinder bore gauge for bore diameter, ovality and taper. |

| 11 |

Measurement of worn out IC engine piston clearance between cylinder and piston. |

| 12 | Measurement of surface roughness using surface roughness tester. |

| 13 | Measurement of co-ordinates of two or more than two holes using surface plate, angle plate, Height Gauge, dial indicator and slip gauges. |

| 14 | Measurement of a profile using profile projector. |

| 15 | Study and use of Auto-Collimator. |

FOURTH SEMESTER

HYDRAULICS & PNEUMATICS

| Sr. No. | LIST OF PRACTICALS |

| 1 | Measurement of pressure head by employing: i) Piezometer tube ii) Single and double column manometer. |

| 2 | To Find out the value of coefficient of discharge for a venturimeter. |

| 3 |

Measurement of flow by using venturimeter. |

| 4 |

Verification of Bernoulli’s theorem. |

| 5 |

To find coefficient of friction for a pipe (Darcy’s friction). |

| 6 | To study hydraulic circuit of an automobile brake and hydraulic ram. |

| 7 | Study the working of a Pelton wheel and Francis turbine. |

| 8 | To study a single stage centrifugal pump for constructional details and its operation to find out its normal head and discharge. |

STRENGTH OF MATERIALS

| Sr. No. | LIST OF PRACTICALS |

| 1 | Tensile test on bars of Mild steel and Aluminum. |

| 2 |

Bending tests on a steel bar or a wooden beam. |

| 3 |

Impact test on metals. a) Izod test. b) Charpy test. |

| 4 |

Torsion test of solid specimen of circular section of different metals for determining modulus of rigidity. |

| 5 | To determine the stiffness of a helical spring and to plot a graph between load extension. |

| 6 | Hardness test on different metals. |

| 7 | Note : All the tests need to be done as per prescribed Indian standards. |

THERMODYNAMICS - I

| Sr. No. | LIST OF PRACTICALS |

| 1 |

Determination of

temperature by:- a) Thermocouple. b) Pyrometer. c) Infrared thermometer. |

| 2 | Demonstrate of mountings and accessories on a boiler. |

| 3 | Study of boilers (through industrial visit). |

| 4 | Demonstrate the working of air compressor. |

| 5 | Demonstration of heat transfer through conduction, convection and Radiation. |

| 6 | Study of working of high pressure boiler. |

| 7 | Study the working of Lancashire boiler and Nestler boiler. |

FIFTH SEMESTER

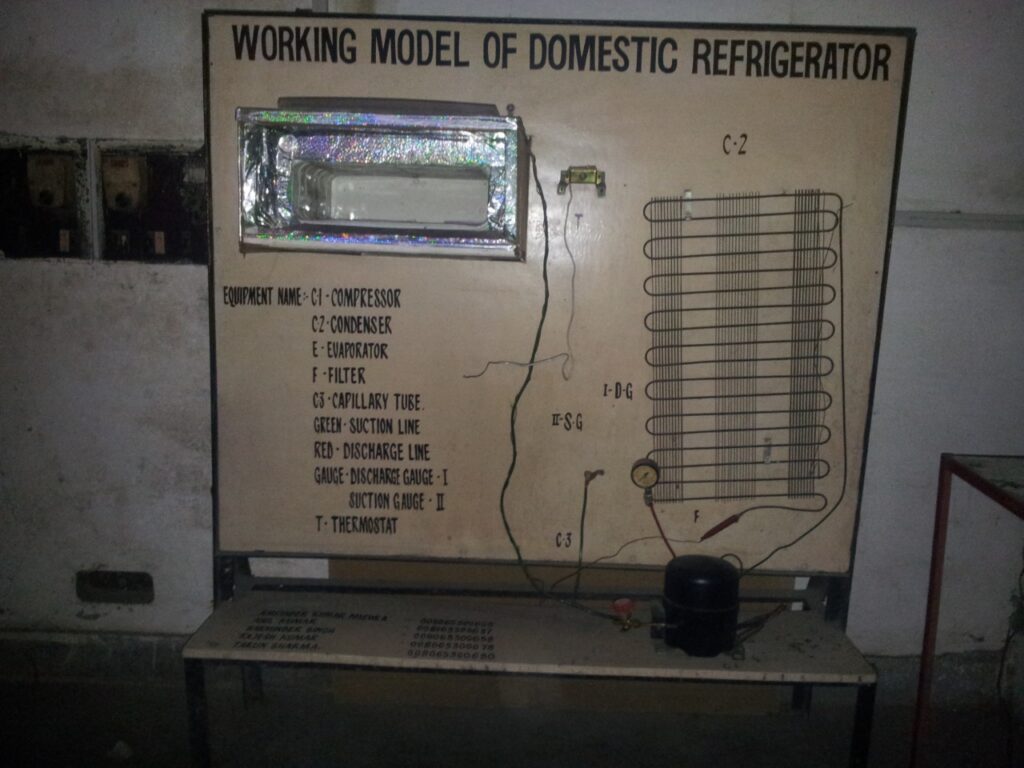

REFRIGERATION AND AIR CONDITIONING

| Sr. No. | LIST OF PRACTICALS |

| 1 | Identify various tools of refrigeration kit. |

| 2 | Practice in cutting, bending, flaring, swaging and brazing of tubes. |

| 3 | Study of thermostatic switch, LP/HP cut out overload protector filters, strainers and filter driers. |

| 4 | Identify various parts of a refrigerator and window air conditioner. |

| 5 | To find COP of Refrigeration system. |

| 6 | To measure air flow using anemometer. |

| 7 | Charging of a refrigerator / air conditioner. |

| 8 | To defect faults in a refrigerator / air conditioner. |

| 9 | Visit to an ice plant or cold storage plant or central air conditioning paint. |

THERMODYNAMICS - II

| Sr. No. | LIST OF PRACTICALS |

| 1 | Dismantle an IC engine and note down the condition of various parts, removal and fitting of piston, rings, measuring of bore size, crank shaft ovality and assemble it. |

| 2 | Dismantle a carburetor. |

| 3 | Servicing of petrol injection system. |

| 4 | Valve servicing, grinding, lapping and fitting mechanism and tappet adjustment. |

| 5 | Inspection of ignition system of a multi-cylinder engine stressing ignition timings, setting, fixing order and contact breaker; gap adjustment, spark plug cleaning. |

| 6 | Service of cooling and lubrication system of IC engine and note down the functioning/testing of various components. |

| 7 | Morse test on multi-cylinder petrol engine. |

| 8 | Determination of BHP by dynamometer. |

| 9 | Local visit to roadways or private automobile workshop. |

| 10 | Draw layout of modem automobile workshop and note down the special tools and equipments in each shop. |

COMPUTER AIDED DRAFTING AND MODELING

| Sr. No. | LIST OF PRACTICALS |

| 1 | Introduction to AutoCAD commands. |

| 2 |

Detail and assembly drawing using AUTOCAD. |

| 3 | Isometric Drawing by CAD using Auto CAD. |

| 4 | Introduction to Solid works : (i) Introduction to Sketcher: Sketch Entities, Sketch Tools, Blocks, Dimensioning (ii) Assembly |

SIXTH SEMESTER

AUTOMOBILE ENGINEERING

| Sr. No. | LIST OF PRACTICALS |

| 1 |

Fault and their remedies in Battery Ignition system. |

| 2 | Adjustment of Head Light Beam (ii) Wiper and Indicators |

| 3 |

Dismantling and inspection of : (i) AC Pump (ii) SU Pump |

| 4 | Dismantle : (i) rear axle (ii) differential and find out the gear ratio of crown wheel & driven sun gear and planet pinion. |

| 5 | Fault finding practices on an automobile – four wheelers (petrol/ diesel vehicles). |

| 6 | Servicing/Tuning of a 2 wheeler/4 wheeler. |

| 7 | Servicing of hydraulic brakes : a) adjustment of brakes b) bleeding of brakes c) fitting of leather pads |

| 8 | Tuning of an automobile engine. |

| 9 | Testing and Charging of an automobile battery and measuring cell voltage and specific gravity of electrolyte. |

| 10 | Changing of wheels and inflation of tyres, balancing of wheels. |

| 11 | Measuring spark gap, valve clearance and ring clearance; carrying out cleaning operations for adjustment |

CNC MACHINES AND AUTOMATION

| Sr. No. | LIST OF PRACTICALS |

| 1 |

Study the constructional details of CNC lathe. |

| 2 |

Study the constructional details of CNC milling machine. |

| 3 | Study the constructional details and working of:– Automatic tool changer and tool setter – Multiple pallets – Swarf removal – Safety devices |

| 4 |

Develop a part programme for following lathe operations and make the job on CNC lathe and CNC turning center : – Plain turning and facing operations – Taper turning operations – Operation along contour using circular interpolation |

| 5 |

Develop a part programme for the following milling operations and make the job on CNC milling : – Plain milling – Slot milling – Contouring – Pocket milling |

| 6 |

Preparation of work instruction for machine operator. |

| 7 |

Preparation of preventive maintenance schedule for CNC machine. |

| 8 | Demonstration through industrial visit for awareness of actual working of FMS in production. |

| 9 |

Use of software for turning operations on CNC turning center. |

| 10 |

Use of software for milling operations on machine centres. |

|

List of Major Equipment |